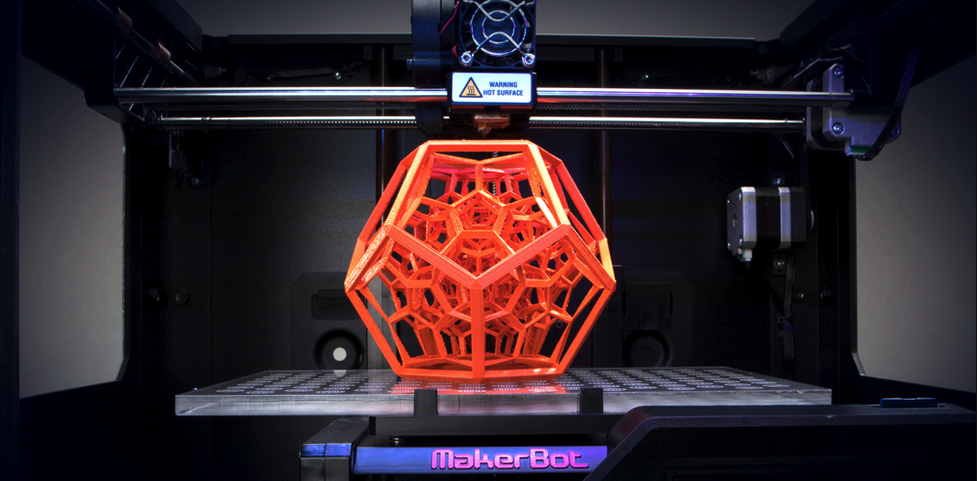

3D printing and the technology behind it is truly amazing. People are already creating some innovative and wondrous things. Some of the successfully printed and fully functional items out there include weapons, instruments, medical models and prosthetics, smartphone cases and even fabrics.

One company even 3D-printed an entire house, and for only $10,000 and in less than 24 hours. That’s a fraction of what it would cost to build a home — even a manufactured one — out of conventional materials and with traditional methods.

As time goes on, we’ll start to see much more done with 3D printing technology. The possibilities are truly endless when it comes to 3D printing. Just take the following examples into consideration:

3D Printing to Improve Running Shoes and Workout Gear

Running and training shoes are developed using injection molding techniques. This means the manufacturer — like Nike or New Balance — takes the shell and injects foam or cuts it to size and then places it strategically inside the shoe. Ultimately, this is what gives running shoes their shock absorption features and makes them a healthier fit for runners and extreme athletes.

Running and training shoes are developed using injection molding techniques. This means the manufacturer — like Nike or New Balance — takes the shell and injects foam or cuts it to size and then places it strategically inside the shoe. Ultimately, this is what gives running shoes their shock absorption features and makes them a healthier fit for runners and extreme athletes.

But thanks to 3D printing, it’s now possible to construct shoes from the ground up, one layer at a time. This creates a stronger and more reliable shoe. Perhaps even more interesting is that this method may be adapted so athletes can order their own custom-fit footwear and gear.

Imagine a running shoe that’s entirely designed to match the contours and edges of your feet. Ever had to wear shoes that are much too wide or narrow? Ever had to wear shoes for people with remarkably straight feet, yet yours are curved, or vice versa?

Later in 2017, Adidas is launching a unique production facility called the Speedfactory in Atlanta. The idea is to create and deliver custom, cutting-edge gear for US-based retailers and customers. It will eventually roll out to include everyone, not just athletes, and we’ll all be able to get a decent pair of custom shoes, which hopefully are much more comfortable and inviting.

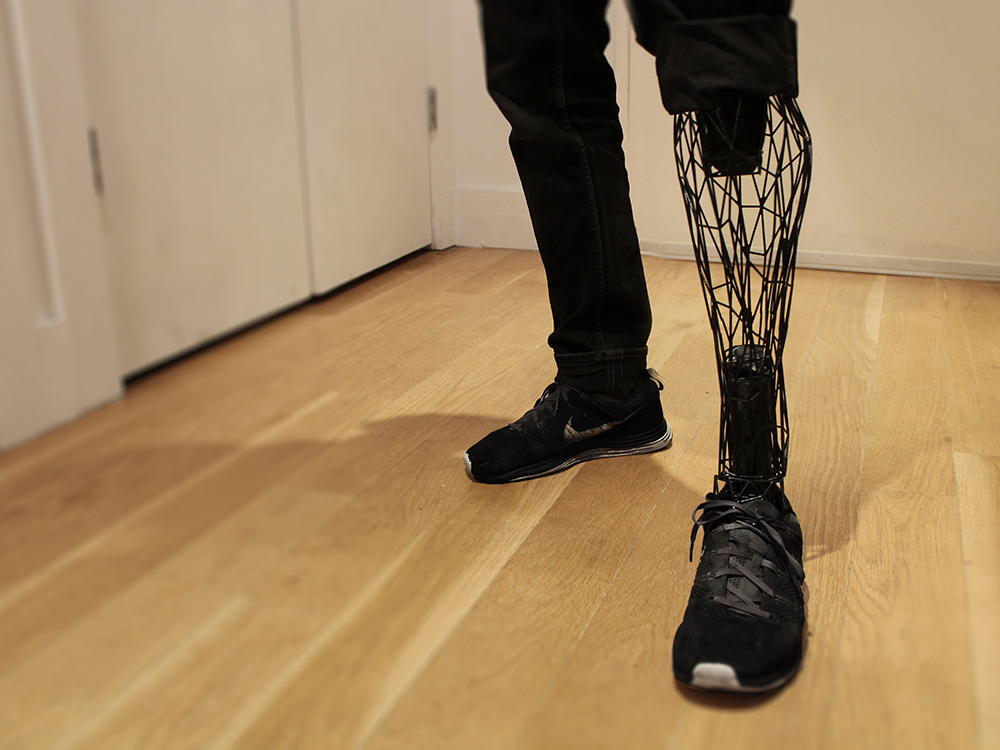

3D Bio-Printing for Prosthetics and Tissue Engineering

This next concept seems remarkable, yet strange. Imagine 3D bio-printed objects like organs, body parts, and even prosthetics.

Admittedly, it’s tough to imagine someone with a 3D-printed nose, vein or limb, but that’s exactly where the technology is going. Believe it or not, there are bio-safe materials that can be used in place of living tissue. And it’s just as feasible to print things with real living tissue! The living cells are cultured and monitored to grow in a certain way, while the printing process can help the finished organ turn into what’s needed, like an ear or a tongue.

Right now, the industry is still researching and experimenting with the technology to see what can be done. Already, we’ve seen 3D-printed skin, organs and more.

3D-Printed Medical Models

Sure, doctors and students can always practice on cadavers, but it’s still not exactly what you’d call ideal. For starters, there may not always be a body or cadaver to work with. Then, there’s no guarantee the body for research will be in the same shape or form as a living, breathing patient.

Thanks to 3D printing, however, medical students, professionals, and doctors can practice on life-sized replicas. Brain surgeons, for example, have the ability to practice procedures and map out surgeries on a realistic model, developed entirely with 3D printing technology.

Think of the implications of this method being used for a variety of other medical procedures. It’s possible to print other organs, like a heart or lungs, and even full limbs. And because of the way 3D printing works — building layer by layer — it’s possible to create a realistic model complete with inner components and even skin.

These are just a few examples showcasing what 3D printing can do. What are other 3D printing applications you excited about? Tell us in the comments section below.